|

| |

|

| |

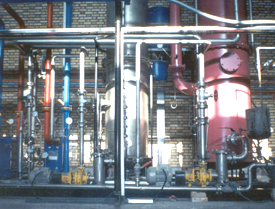

Gaslabs has developed a new technology of EXTRACTING CO2

FROM BIOMASSES. It has set up serveral plants running on Biomasses

and demands are pouring. while introducing this technology for the

first time in the world Gaslabs Asia is constantly working on design

innovations of its plant based on fertilizer gases, breweries and

distilleries to extract even more wealth from waste. Gaslabs' flue

gas plant uses boiler or any furnace flue gas as a raw material

thus doing away with costly liquid fuel which is generally costlier

in Asian contexts.

The

flue and biomass gas plants can be designed in the different capacities

ranging from 30kg per hour to 2000kg per hour depending on

the available input and client requirement.

Other options may be the plants that run on waste hard coke, nut

coke, breeze coke and pearl coke.

|

|

| |

|

|

|

Gaslabs

Asia plants are designed to use industrial bye products as their

raw material, which works as a boon for DISTILLARIES and

BREWERIES where fermented gases are produced in plenty and

otherwise would go waste. GASLABS ASIA PLANTS RECOVER ODOUR-FREE,

FOOD GRADE CO2 FROM THEM. Plants themselves

are 100% POLLUTION-FREE causing no environmental imbalances, instead

they capture CO2 which otherwise would have been mingled

with the environment.

Gas quality is guaranteed to be food grade and 99.99% pure in

most cases. These plants are not only cost-effective in running

but they are MOST REASONABLY PRICED to install too!-as they

comparative study vis-a-vis to their features will reveal

In our CO2 production plants based on any fuel burning

we can co-produce N2 and DISTILLED WATER

as well. |

| |

|

| |

Undoubtedly

Europe was first to use CO2 for industrial purposes.

It's countries designed various plants and innovated new technologies,

spreading them out to the world.

But unfortunately, in design Western Industry even now supports

the 'Disposable' tag. A good reason for this may be the cost of

repair & maintainence though. While the opposite is true for

Asia. Though Gaslabs Asia makes widest range of plants ( from semi-automatic

to full PLC computer controlled) it supports the Asian line. All

Gaslabs' plants are MODULAR IN DESIGN with JUST RIGHT AUTOMATION,

thus making maintainence and repair easy & cheap. Gaslabs' plants

also have plenty of space in their floor plan which is relatively

less costly in Asia.

JUST HOW MUCH AUTOMATION does a client need? Many times a total

automation, for an Asian environment may not prove to be as effective

and hassle-free as manual or semi automated processes. At Gaslabs

Asia, our first concern is plant uptime, productivity and automation-in

that order. |

|

| |

|

| |

We

believe that New Ideas should prove their dependability and we implement

it with conviction. Our own CO2 plants work as testing

ground to our innovations before they are commercially made available

to our clients. This also gives us an opportunity to understand

their problems which they might encounter in future. We make every

attempt to eliminate them at design level itself.

At Gaslabs Asia new ideas get into practical shape only when they

have withstood our rigorous testing measures and have proven their

dependability.

For example our Biomass Plant took 5 long years to see the light

of the day. |

| |

|

| |

carbon-di-oxide gas

plant, CO2 gas plant |

|

| |

| |

| GASLABS

ASIA, SS FOUNDRY CHEMICAL INDIA PVT. LTD. |

Site

Designed by 44degrees.com

Best resolution 800 by 600 |

|